+86-13516964051

+86-13516964051 Surface roughness testing methods and standards for aluminum castings

Surface Roughness Testing Methods and Standards for Aluminum Castings

I. Key Impacts of Surface Roughness on Aluminum Castings

The surface roughness of aluminum castings directly affects not only the appearance and texture of the product but also its core performance characteristics:

* Sealing and Fit: Excessive roughness can easily lead to wear of seals and fluid leakage. Strict control of Ra/Rz parameters is necessary in precision assembly.

* Corrosion Resistance: Uneven surfaces are prone to media residue, accelerating oxidation or electrochemical corrosion, especially in marine and chemical environments.

* Coating Adhesion: Post-processing techniques such as spraying and anodizing have specific requirements for surface roughness; excessively rough or smooth surfaces will affect coating adhesion.

* Fluid Dynamics Performance: The internal surface roughness of castings such as pipes and valve bodies affects fluid resistance and must be matched to operating conditions.

II. Core Methods for Surface Roughness Testing of Aluminum Castings

(I) Contact Measurement Method

Stylus Profilometer

Principle: A diamond probe (tip radius 2-10μm) slides uniformly along the surface of the casting, converting mechanical displacement into an electrical signal. Roughness parameters are then calculated by software.

Advantages: High measurement accuracy (resolution up to 0.001μm), supports multiple parameter outputs such as Ra, Rz, and Rq, suitable for regular surfaces such as planes and cylinders.

Precautions: Before testing, the surface must be cleaned of oil and oxide scale to avoid scratching the Precision Casting with the probe. For complex curved surfaces, a special fixture is required. Comparison Blocks Method

Principle: The roughness level is determined by visual comparison or tactile inspection of the Casting Surface against a standard block (with calibrated Ra/Rz values).

Advantages: Convenient operation, low cost, suitable for rapid on-site screening, commonly used in preliminary quality inspection of mass production.

Limitations: Accuracy depends on operator experience; only qualitative or semi-quantitative judgment is possible; the blocks need to be calibrated periodically.

(II) Non-Contact Measurement Methods

Laser Interferometry

Principle: A laser beam illuminates the casting surface; the microscopic profile of the surface is analyzed through the interference fringes of the reflected light to calculate the roughness parameters.

Advantages: Non-contact, non-destructive, fast measurement speed (≤1 second per measurement), suitable for soft, easily deformable, or precision aluminum castings.

Applicable Scenarios: In-machine inspection of complex curved surfaces (such as impellers, mold cavities) and high-temperature castings. White Light Interferometry (CLE)

Principle: Utilizes the low coherence of white light to acquire the three-dimensional contours of a surface through vertical scanning, achieving nanometer-level precision.

Advantages: Combines high resolution and a large measurement range; visualizes surface morphology and supports parameter analysis such as Ra, Rz, and Sm (contour cell width).

Limitations: High equipment cost; strict requirements for temperature and humidity in the inspection environment (recommended 20±2℃, humidity ≤65%).

Machine Vision

Principle: High-definition camera paired with an optical lens captures surface images; texture features are extracted using image algorithms and converted into roughness data.

Advantages: Enables automated online inspection; suitable for high-speed production lines; supports large-area scanning.

Precautions: Avoid surface reflections that could affect image quality; periodic calibration of the optical system is necessary.

III. Globally Accepted Standards for Surface Roughness Testing

(I) Core International Standards System

ISO Standards (International Organization for Standardization)

ISO 4287:2000: Defines the terminology, parameters, and methods of measurement for surface roughness. Core parameters include:

* Ra (Arithmetic Mean Deviation): The arithmetic mean of the deviations from the centerline of the surface profile; most widely used.

* Rz (Maximum Height): The vertical distance between the highest and lowest peaks within the assessed length, reflecting the degree of surface undulation.

* Rq (Root Mean Square Deviation): More sensitive to the distribution of surface peaks; suitable for precision machinery.

* ISO 1302:2002: Specifies the method for marking surface roughness, including parameter symbols, values, and sampling lengths.

ASTM Standards (American Society for Testing and Materials)

* ASTM B633: Requirements for testing the surface roughness of metal coatings; commonly used in electroplating and spraying processes for aluminum castings.

* ASTM D7127: A general standard for non-contact optical testing methods, clarifying instrument calibration and error control. DIN Standards (Deutsches Institut für Normung)

DIN 4768: Surface roughness classification standard (N1-N12), which is interchangeable with ISO parameters;

DIN EN ISO 14488: Specific testing specifications for aluminum and Aluminum Alloy Castings, covering the influence of casting defects on roughness.

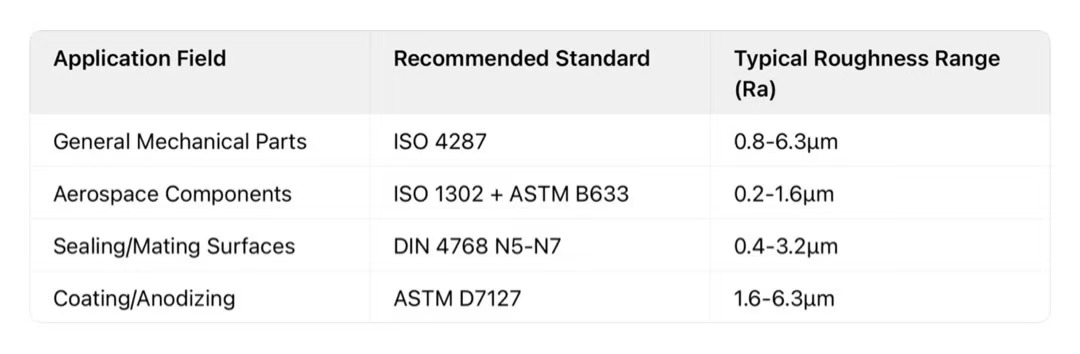

(II) Standard Selection for Common Application Scenarios

IV. Key Considerations in Practical Applications

Surface Pretreatment: Remove defects such as sand holes, burrs, and oxide scale from the casting surface to avoid affecting the test results; oil stains should be wiped with anhydrous ethanol and allowed to air dry before testing.

Sampling Location and Length: According to ISO 4287, the sampling length should include at least 5 profile units. For complex castings, multiple points should be tested on key functional surfaces (such as sealing surfaces and mating surfaces), and the average value should be taken.

Instrument Calibration: Contact instruments require calibration of the probe using standard gauge blocks; non-contact instruments require regular calibration of the optical system to ensure that the measurement error is ≤±5%. Environmental control: Avoid testing in dusty, vibrating, or strong light environments. Temperature fluctuations can cause thermal expansion and contraction of castings, affecting the accuracy of microscopic profile measurement. Parameter interpretation: Different industries have different emphases on parameters. For example, the automotive industry prioritizes Ra, while hydraulic components focus more on Rz (to prevent oil film rupture).