+86-13516964051

+86-13516964051 Alloy composition selection and performance optimization of low-pressure cast aluminum alloys

Alloy Composition Selection and Performance Optimization of Low-Pressure Casting Aluminum Alloys

I. Key Dimensions of Alloy Composition Selection: Element Ratio and Performance Balance

1. Mechanism of Action and Content Control of Core Elements

Silicon (Si): The fundamental strengthening element in low-pressure casting aluminum alloys, improving fluidity by forming a eutectic phase. When the Si content is between 6% and 12%, the alloy's filling ability is optimal, effectively reducing shrinkage defects; exceeding 13% easily leads to the formation of network silicon crystals, which reduces toughness. For example, in the ZAlSi7MgA alloy (Si content around 7%), sodium salt modification treatment changes the eutectic silicon morphology from needle-like to spherical, increasing the elongation to 8.5%.

Magnesium (Mg): Improves strength through precipitation strengthening (forming the Mg₂Al₃ phase) while also improving corrosion resistance. Recommended content is 0.25%-3%; excessive amounts increase the risk of oxide film formation, leading to porosity defects. The 6061-T6 alloy (Mg content 0.8%-1.2%) achieves a yield strength of 276 MPa after T6 Heat Treatment.

Copper (Cu): Significantly improves high-temperature strength, but must be strictly controlled between 0.5%-3.2%. Excessive Cu content reduces fluidity and increases the tendency for hot cracking—due to the formation of low-melting-point eutectic phases at grain boundaries, which easily lead to cracking during cooling.

Iron (Fe): A dual-purpose element; a content of 0.05%-0.8% prevents sticking (forming a FeAl₃ protective film), while content exceeding 1% generates coarse acicular phases, cutting the matrix and reducing toughness. The latest heat-treated-free alloys use Ca element control to transform the Fe phase into a granular form, increasing the Fe tolerance to 2%.

2. Strict Control of Impurity Elements

Zinc (Zn): Content must be below 0.5%. Excessive content will cause electrochemical corrosion and reduce the service life of castings.

Lead (Pb) and Tin (Sn): Total harmful impurities should be ≤0.05%. Their low-melting-point eutectic phase will severely weaken grain boundary strength.

Boron (B): Added as a modifier (0.005%-0.01%), it refines grains by forming AlB₂ crystal nuclei, improving fluidity by more than 30%.

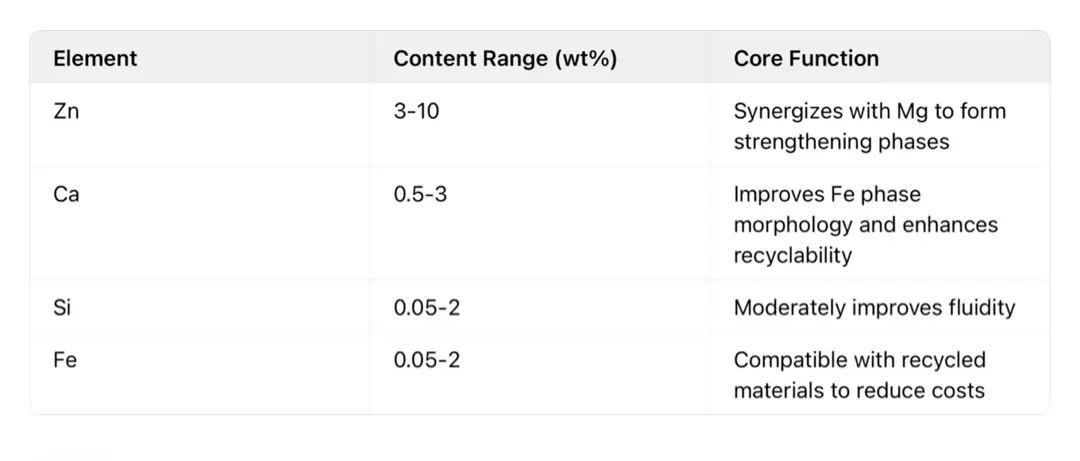

3. Compositional Innovation of Novel Heat-Treation-Free Alloys

Breakthroughs have been achieved in Zn-Mg-Ca alloys to address the problem of coarse grains caused by the low cooling rate (0.5-10 k/s) in low-pressure casting:

II. Three Core Pathways for Performance Optimization

1. Precise Matching of Heat Treatment Processes

T6 Heat Treatment: Applicable to Al-Si-Mg alloys, solution treatment (535±5℃/6-12h) + artificial aging (155℃/3-6h) ensures complete dissolution and uniform precipitation of the strengthening phase. After T6 treatment, the tensile strength of ZAlSi7MgA increased from 200 MPa to 280 MPa;

Local Aging Treatment: For welded parts, such as 6061 alloy, T4 tempering is used after welding to eliminate softening in the heat-affected zone, achieving a joint strength retention rate of 90%.

2. Modification and Microalloying Technology

* Rare Earth Composite Modification: Adding 0.06% cerium (Ce) transforms the β-Fe phase morphology into a granular form, shortens the secondary dendrite arm spacing by 40%, and increases fatigue life by over 50%.

* Titanium (Ti) Microalloying: Adding 0.1%-0.2% Ti in combination with boron forms TiB₂ crystal nuclei, refining the grain size to below 50μm, significantly improving crack resistance.

3. Synergistic Control of Melting and Casting Processes

* Vacuum Melting: Oxygen content is controlled below 10ppm, and hydrogen content ≤0.15ml/100g, reducing porosity defects.

* Cooling Rate Optimization: The cooling rate is increased to 5-10k/s through a mold temperature control system, inhibiting grain growth. Combined with composition adjustments, heat treatment-free strengthening can be achieved.

III. Typical Application Scenarios and Composition Optimization Cases

1. Aerospace Precision Components (ZAlSi7MgA Alloy)

Composition Design: Si 6.5%-7.5%, Mg 0.25%-0.45%, Ti 0.1%-0.2%, with strict control of Cu≤0.1% and Fe≤0.15%;

Optimization Measures: Vacuum melting + sodium salt modification + T6 heat treatment;

Performance Indicators: Tensile strength 225MPa, hardness 60HBS, elongation 5%, meeting ASTM A959-16 standard requirements. 2. Automotive Structural Components (Heat-Free Zn-Mg-Ca Alloy)

Composition Design: Zn 5%-8%, Mg 1%-2%, Ca 0.5%-1.5%, Fe 0.45%-0.8%;

Optimization Measures: Grain refinement treatment + precise composition ratio;

Performance Indicators: Yield strength 210MPa, elongation 6%, recyclability up to 95%, manufacturing cost reduced by 20%.

IV. Industry Frontier Trends: Greening and Intelligentization

Recyclable Alloy Development: By controlling elements such as Ca and Mn, the tolerance for Fe is improved, increasing the application rate of recycled aluminum alloys in low-pressure casting from 30% to over 70%; Composition-Performance Prediction Model: Based on machine learning algorithms, inputting element content and process parameters, it can accurately predict key properties such as tensile strength and elongation, shortening the R&D cycle by 30%; Multifunctional Alloy System: Developing new alloys with both high strength (≥300MPa) and high thermal conductivity (≥150W/(m・K)) to meet the high-end requirements of new energy vehicle motor housings, etc.