+86-13516964051

+86-13516964051 Top OEM Diecast Die Factory: Custom Manufacturing Solutions for Global Brands

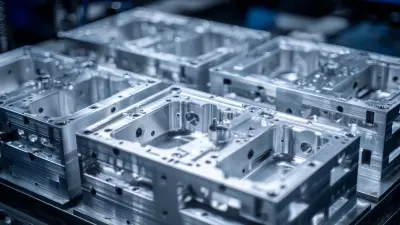

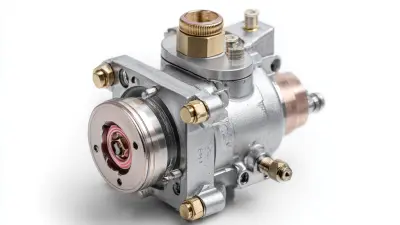

As a premier player in the diecast industry, we focus on delivering top-quality OEM solutions for businesses in need of exceptional products. Our dedicated Diecast Die factory specializes in manufacturing precision-engineered items designed to your exact requirements. Partnering with us grants you access to a network of dependable factories and manufacturers, ensuring each piece adheres to our strict quality standards. With extensive industry experience, we comprehend the subtleties of buyer behaviors and market demands. Whether you require customized designs or large-scale orders, we emphasize your satisfaction at every stage of the manufacturing process. Our experienced team is ready to support you from the initial concept all the way to final product delivery.Why China’s Global Leading Diecast Die Factory From Concept to Delivery Factory-Direct Excellence

In the dynamic landscape of global manufacturing, China's diecast industry stands out as a beacon of excellence, particularly in the realm of diecast die production. The journey from concept to delivery is meticulously crafted, showcasing not only the advanced technological capabilities but also a deep commitment to quality that has come to define leading manufacturers in this sector. As the demand for high-quality parts and components in the automotive industry continues to rise, the importance of choosing a reliable diecasting partner cannot be overstated. The process begins with innovative design and engineering, where state-of-the-art technology meets skilled craftsmanship. Manufacturers employ cutting-edge software and machinery to transform ideas into tangible products, ensuring that each aspect of the die is optimized for functionality and durability. Rigorous quality control measures are integrated throughout the production process, guaranteeing that every component meets the highest industry standards. This dedication to excellence not only enhances product reliability but also fosters long-term partnerships with global clients seeking dependable solutions. Additionally, the direct factory-to-consumer model significantly benefits procurement partners. By eliminating intermediaries, clients can enjoy more competitive pricing and greater transparency in the manufacturing process. This streamlined approach not only expedites delivery times but also enables manufacturers to respond swiftly to market changes and customer demands. In a world where efficiency and quality are paramount, China's diecast die factories exemplify how innovation and commitment can culminate in an exceptional procurement experience, making them an optimal choice for businesses in the automotive sector seeking reliable partners in their supply chain.

Why China’s Global Leading Diecast Die Factory From Concept to Delivery Factory-Direct Excellence

| Dimension | Description | Value |

|---|---|---|

| Production Capacity | Annual units manufactured | 5,000,000 units |

| Lead Time | Time from order to delivery | 6 weeks |

| Quality Certification | ISO certification level | ISO 9001 |

| Materials Used | Type of materials in production | Zinc alloy, ABS plastic |

| R&D Investment | Allocation for product innovation | $2 million annually |

| Employee Count | Total workforce | 800 employees |

| Export Markets | Regions served | North America, Europe, Asia |

Curated Selection of Global Leading Diecast Die Factory Market Leader Manufacturers You Can Rely On

A

Anthony Baker

This product is outstanding! The customer service team was professional and helped me with all my inquiries.

10 May 2025

P

Peyton Williams

Fantastic product quality! I was very impressed with the knowledgeable support staff throughout the process.

12 June 2025

E

Elias Young

Incredible quality craftsmanship! The customer service team was knowledgeable and made the process a breeze.

25 June 2025

C

Cecilia Green

This product met all my expectations for quality! The customer service team was both friendly and professional.

26 June 2025

H

Hazel Mitchell

Love the durability and quality of this item! Customer service was very professional and knowledgeable, which I appreciated.

24 May 2025

J

Jasmine Clark

What a high-quality product! The support team was thorough, knowledgeable, and very professional in handling my queries.

03 July 2025