+86-13516964051

+86-13516964051 Top Zinc Die Casting Manufacturers in China: Wholesale Suppliers & Factories

As a buyer seeking dependable ODM suppliers, I would like to express my confidence in the premier Zinc Die Casting factories in China, particularly Yongkang Hantai Industry And Trade Co., Ltd. Their dedication to quality and precision has positioned them as a top choice in the industry. The extensive range of custom designs and their ability to tailor solutions to specific project needs reinforce my collaboration with them. Their knowledgeable team ensures clear communication throughout the process. Coupled with competitive pricing and reliable on-time delivery, partnering with them has been seamless. For those considering zinc die casting suppliers, I highly recommend the exceptional services of Yongkang Hantai, which truly reflects the quality and expertise valued in a long-term business partnership.In-Depth Analysis of Methods China Top Zinc Die Casting Factories For the Current Year in 2025

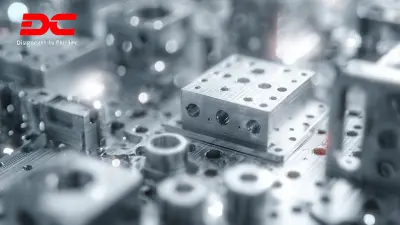

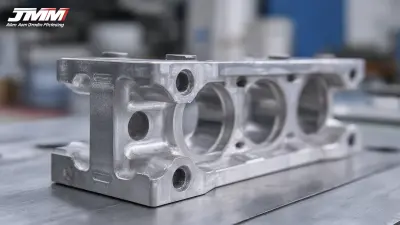

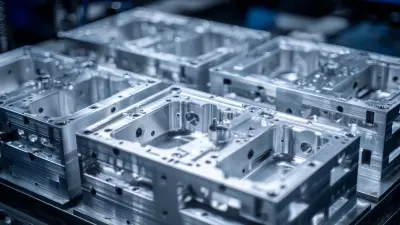

In the competitive landscape of the automotive industry, the importance of high-quality components cannot be overstated. As we delve into the analysis of top zinc die casting factories in China for the current year in 2025, it is evident that these manufacturers are embracing advanced technologies and innovative practices to meet global procurement demands. With a rich history and commitment to quality, Chinese die casting factories are increasingly becoming key players in supplying critical parts that ensure vehicle efficiency and safety. One of the standout trends this year is the integration of automation and smart manufacturing processes. This evolution not only enhances production efficiency but also minimizes defects and waste, making these factories a reliable source for global buyers. Additionally, the focus on sustainability is reshaping manufacturing practices, with many facilities investing in eco-friendly technologies and materials. As global procurement strategies increasingly prioritize sustainability, collaborating with factories that share this commitment can provide a significant competitive edge. Moreover, the versatility and adaptability of Chinese zinc die casting producers allow them to cater to diverse client specifications and industry requirements. Buyers are now looking for partners that not only deliver quality parts but also understand the nuances of the automotive sector, including regulatory compliance and rapid prototyping. With these capabilities, Chinese manufacturers are poised to strengthen their position in the global supply chain, ultimately creating opportunities for buyers seeking reliable, high-quality components for their automotive needs.

In-Depth Analysis of Methods China Top Zinc Die Casting Factories For the Current Year in 2025

| Factory Location | Production Capacity (tons/year) | Key Technologies Used | Market Share (%) | Sustainability Practices |

|---|---|---|---|---|

| Eastern China | 1500 | High Pressure Die Casting, CNC Machining | 25 | Recycling, Energy Efficient Processes |

| Southern China | 2000 | Vacuum Die Casting, Surface Treatment | 30 | Water Conservation, Waste Minimization |

| Northern China | 1200 | Low Pressure Die Casting, Heat Treatment | 20 | Emissions Control, Eco-friendly Materials |

| Western China | 800 | Die Casting, Injection Molding | 10 | Renewable Energy Use, Employee Training Programs |

| Central China | 1800 | Advanced Die Casting Techniques, Robotic Automation | 15 | Carbon Footprint Reduction, Recycling Initiatives |

Why Opt For China Top Zinc Die Casting Factories Industry Leaders Where Service Meets Innovation

E

Ethan Smith

This product is top-notch in quality. I appreciated the after-sales support, which was both knowledgeable and friendly. A great experience!

03 July 2025

H

Henry Lee

This product is wonderful! The after-sales service was top-notch, with staff that are true experts in their field.

20 June 2025

S

Scarlett Phillips

This product performs excellently! The customer service team was not only professional but also compassionate in addressing my concerns.

29 May 2025

L

Landon Davis

Impressive quality product! The after-sales service was prompt and truly professional. Highly recommend!

21 June 2025

C

Cecilia Green

This product met all my expectations for quality! The customer service team was both friendly and professional.

26 June 2025

A

Asher Baker

The commitment to quality is evident! Their after-sales support team went above and beyond in professionalism.

26 June 2025