+86-13516964051

+86-13516964051

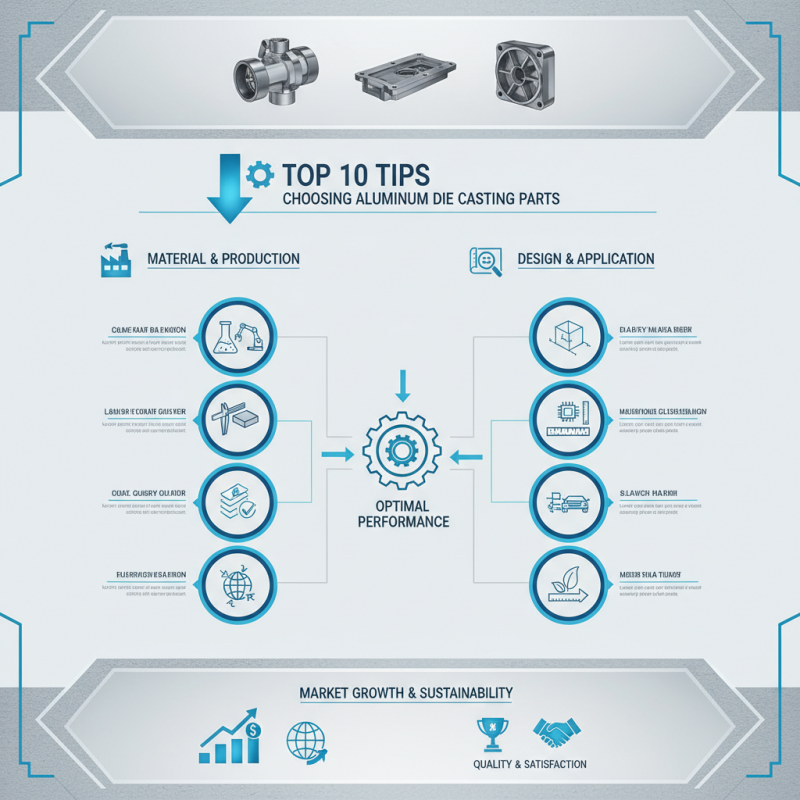

Aluminum die casting parts have become a cornerstone in various industries due to their superior strength-to-weight ratio and excellent corrosion resistance. According to a recent industry report by MarketsandMarkets, the global aluminum die casting market size is projected to grow significantly, reaching USD 6.5 billion by 2027, driven by the increasing demand for lightweight components in automotive and aerospace applications. This noteworthy growth underscores the necessity for manufacturers and engineers to carefully select the right aluminum die casting parts to ensure optimal performance and efficiency in their projects.

When selecting aluminum die casting parts, several critical factors come into play, including material specifications, production capabilities, and part design complexity. Industry experts recommend evaluating suppliers based on their ability to adhere to stringent quality standards, as the tolerances and surface finishes of die cast components can greatly influence the overall integrity and functionality of the final product. As the demand for precision and customization heightens in sectors such as electronics and consumer goods, understanding these key aspects will empower businesses to make informed choices that align with their project requirements and long-term sustainability goals.

By focusing on the best practices for selecting aluminum die casting parts, manufacturers can leverage the advancements in die casting technology and material science to stay competitive in an ever-evolving market landscape. With the right strategic approach, companies can optimize their production processes while ensuring that their components meet or exceed industry standards, thereby enhancing overall product quality and customer satisfaction.

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold to create intricate shapes and designs. This process is favored in various industries due to its ability to produce parts with excellent dimensional accuracy and a smooth surface finish. According to a report by MarketsandMarkets, the global aluminum die casting market is expected to reach approximately $12.5 billion by 2025, highlighting its growing significance in sectors such as automotive, aerospace, and consumer electronics.

The benefits of aluminum die casting extend beyond just cost-effectiveness. The material itself offers a high strength-to-weight ratio, which has become increasingly important in industries aiming for fuel efficiency and emission reductions. A study from the Aluminum Association noted that lightweight aluminum components can reduce vehicle weight by as much as 50% compared to traditional materials, directly impacting energy consumption and performance. Furthermore, the ability to create complex geometries not only enhances design flexibility but also allows for the integration of multiple components into a single part, reducing assembly time and costs. This makes aluminum die casting an optimal choice for manufacturers looking to innovate while maintaining efficiency.

When selecting aluminum die casting parts for your project, understanding the specific requirements is crucial. This involves evaluating factors such as the intended application, load-bearing needs, and environmental conditions that the parts will endure. According to a report from the Aluminum Association, over 90% of manufacturers emphasize the importance of precise specifications to ensure optimal performance and durability in their die-cast products.

It's essential to define your project’s requirements, including dimensions, tolerances, and surface finishes. For instance, if the parts are intended for automotive applications, they may require higher strength and thermal conductivity to meet safety and efficiency standards. Tip: Always communicate your project needs clearly to your supplier, as effective collaboration can lead to customized solutions that precisely match your specifications.

Another critical aspect to consider is the production volume. An Industry Week report indicates that the shift towards automation in die casting processes has resulted in improved consistency and reduced lead times for high-volume production. Tip: If your project demands large quantities, consider suppliers that can leverage technology for scale without compromising quality. By thoroughly identifying these specifics, you can ensure your aluminum die casting parts meet the exact demands of your project.

When evaluating the quality of die casting manufacturers, it is essential to consider several key factors that can significantly impact the outcome of your project. First, you should assess the manufacturer's reputation and experience in the industry. A company with a long-standing history and positive customer feedback is likely to have developed effective processes and practices that ensure high-quality production. Look for certifications and industry standards that the manufacturer adheres to, as these can serve as indicators of their commitment to quality and reliability.

In addition to reputation, it’s important to examine the manufacturer’s technological capabilities and equipment. A state-of-the-art facility equipped with the latest technology can greatly enhance the precision and consistency of the die casting parts. Furthermore, inquire about the manufacturer’s quality control measures. Robust quality assurance processes, including testing and inspection protocols, can help identify defects early in the production process, minimizing waste and ensuring that the final products meet your specifications. Taking these factors into account will help you make an informed decision when selecting a die casting manufacturer for your project.

| Criteria | Description | Importance Rating (1-5) |

|---|---|---|

| Material Quality | Assess the purity and properties of aluminum used in casting. | 5 |

| Manufacturer Experience | Look for manufacturers with years of specialized experience in die casting. | 4 |

| Quality Certifications | Check for ISO and other quality certifications that indicate manufacturing standards. | 5 |

| Production Capacity | Ensure the manufacturer can meet your volume needs without delays. | 4 |

| Technology and Equipment | Evaluate the technology and machinery used for die casting processes. | 5 |

| Post-Casting Services | Consider if the manufacturer offers finishing and assembly services. | 3 |

| Customer Support | Look at the level of support provided during and after the order process. | 4 |

| Sample Quality | Request samples to evaluate the quality and precision of the parts. | 5 |

| Price Comparison | Compare prices among manufacturers while considering quality. | 3 |

| Delivery Time | Assess the lead times and punctuality of different manufacturers. | 4 |

When it comes to aluminum die casting parts, understanding the cost factors involved can significantly influence your project's budget. One primary aspect to consider is the complexity of the design. More intricate designs typically require advanced tooling and longer production times, which can escalate costs. Therefore, it is crucial to assess your design carefully, balancing functionality with manufacturability.

Another vital cost factor is the volume of parts you need. Generally, higher quantities can reduce the per-unit cost due to economies of scale. If you anticipate a high demand, investing in high-quality tooling upfront can yield long-term savings. Conversely, for lower quantities, you might need to consider less complex designs or alternative manufacturing methods to keep costs manageable.

Tips for choosing the right aluminum die casting parts include selecting a reliable supplier who offers transparent pricing and has a proven track record of quality. Additionally, ensure that you thoroughly evaluate the required tolerances for your parts. Tight tolerances can increase production costs, so understanding where you can compromise without compromising quality is crucial. Finally, don’t forget to factor in post-processing needs, as these can add significant costs depending on surface finishes or additional machining required.

This chart illustrates the primary cost factors associated with aluminum die casting parts. Understanding these factors can help you make more informed decisions when choosing aluminum die casting for your project.

Sustainability has become a crucial aspect of the manufacturing industry, particularly in die casting processes. When selecting aluminum die casting parts for your project, it's essential to consider the environmental impact of your choices. Aluminum is a highly recyclable material, with efficient recycling processes that consume significantly less energy compared to the extraction and refining of new aluminum.

By opting for die casting components made from recycled aluminum, businesses can reduce their carbon footprint and promote a circular economy, where materials are reused and reprocessed rather than discarded.

Additionally, evaluating the production practices of die casting suppliers can provide insight into their commitment to sustainability. Factors such as energy consumption, waste management, and emissions control are critical elements to consider. Many manufacturers are now adopting eco-friendly practices, including using renewable energy sources and implementing lean manufacturing techniques to minimize waste.

By choosing suppliers that prioritize sustainability, companies not only lessen their environmental impact but also demonstrate social responsibility in their operations, appealing to an increasingly eco-conscious market.